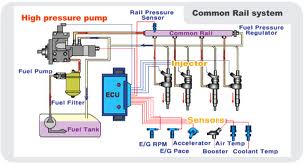

Common Rail Diesel

The most common type of CRD (common rail diesel) injection system we see in the North American light/heavy and some medium duty(GM/Isuzu) markets is the Bosch system or a derivative. The only exception would be the Siemens two-point pressure controlled system found on the 6.4L Powerstroke/VT 365 International which is covered in 6.4L Powerstroke Diesel Fuel System Failures.

The Bosch CP system used on the Duramax, and the Denso derivative used on the Isuzu do not use a lift pump between the tank and CP pump (exception, G series GM).

The CP pump incorporates a lift pump built into the rear of the unit which draws fuel from the tank and is capable of generating pressures of up to 180 PSI. This lift pump sends fuel to the high-pressure portion of the CP pump where it is pressurized up to 26,000 PSI depending on demand. This CP pump, CP1-CP3 use Boyels law, increased volume=increased pressure. The issue with this system is that pressure reduction is handled through a mechanical function of the injector, the diagram shows a two-point pressure control system. It incorporates a pressure regulator in the fuel rail to rapidly reduce fuel pressure.

Most of the injector issues I see on the Isuzu 5.2l and LB7 Duramax CRD can be attributed to mechanical wear caused by rail pressure reduction which is a function of the injector itself. This can cause the PCM to default or limp reducing engine output or a no start condition due to excessive injector back leakage.

The latest Bosch system used by the big three is the CP4. It incorporates both volume control and pressure regulation for more precise fuel pressure control which results in more power and cleaner emissions. It also has higher operating pressures than previous systems. Up to 35,000 PSI.